In today’s competitive market environment, manufacturing companies rely heavily on their production equipment. These machines not only enhance productivity but also ensure product quality and customer satisfaction. Specifically, for the production of hot melt welding machines, laser cutting equipment, die-casting equipment, and sheet metal welding equipment are indispensable.

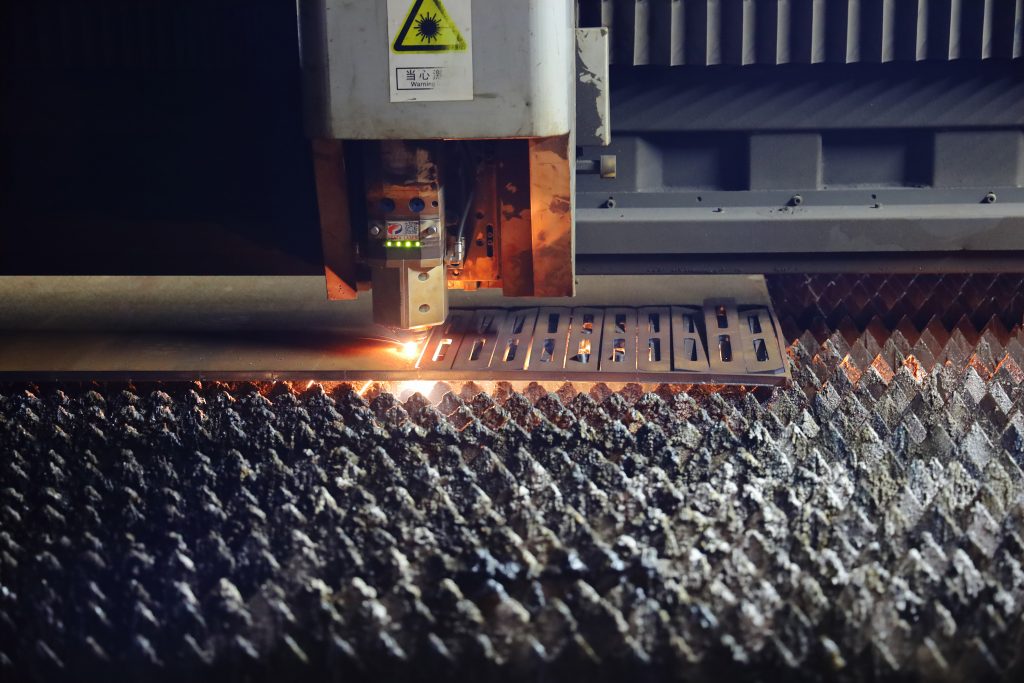

Laser cutting equipment plays a crucial role in the production of hot melt welding machines. It accurately cuts various metal materials, including steel, aluminum alloys, and other materials requiring high-precision cutting. Through laser cutting, we ensure that the components of our hot melt welding machines have precise dimensions and shapes, thereby improving product quality and performance.

Die-casting is essential for manufacturing high-quality hot melt welding machines. Die-casting equipment injects metal materials into molds under high pressure to form the required parts and components. This process ensures product strength and durability while also increasing production efficiency. Equipped with advanced control systems, our die-casting equipment ensures that every part meets strict quality standards.

Sheet metal welding is a critical step in manufacturing hot melt welding machine enclosures and components. Our sheet metal welding equipment welds metal sheets into various shapes and sizes of enclosures, ensuring products have excellent appearance and durability. Our welding processes are carefully designed to ensure the strength and sealing of weld joints, thereby enhancing product reliability and performance.

Laser cutting equipment, die-casting equipment, and sheet metal welding equipment are essential for our company’s production of hot melt welding machines. With these advanced production machines, we can ensure the production of high-quality, high-performance hot melt welding machine products that meet customer needs and maintain competitiveness. We will continue to invest in advanced technology and equipment to continuously improve our production capacity and product quality, achieving the long-term development goals of the company.